DCS and PLC systems for the management and control of the Planned Maintenance System and all systems that guarantee advanced automation of hull services. Applications that can be extended transversally in civil, industrial and military fields. The implementation of these complex systems is managed entirely in our office thanks to the specific technical knowledge acquired with daily commitment and dedication.

We are interested in the control applications, that is composed to various parts of the naval-type platforms, from propulsion, to the fire-fighting system to that of generating electricity on board. All systems are made in a workmanlike manner and strictly following the project specifications provided by the customer. These automations allow a simpler and leaner management of all the most critical operations, reducing the risk of errors and increasing safety on board. Our systems equip civilian and military ships and it is also thanks to this wide range that we are able to combine the best technologies to obtain an unparalleled final result.

Don’t miss the boatMarine

Smart management of

Marine System

The rudder became smart, valve control at your fingertips.

Efficient, precise systems that don’t miss.

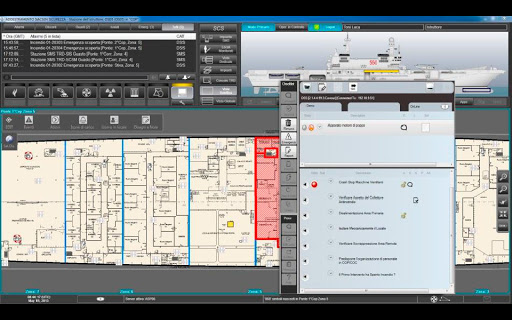

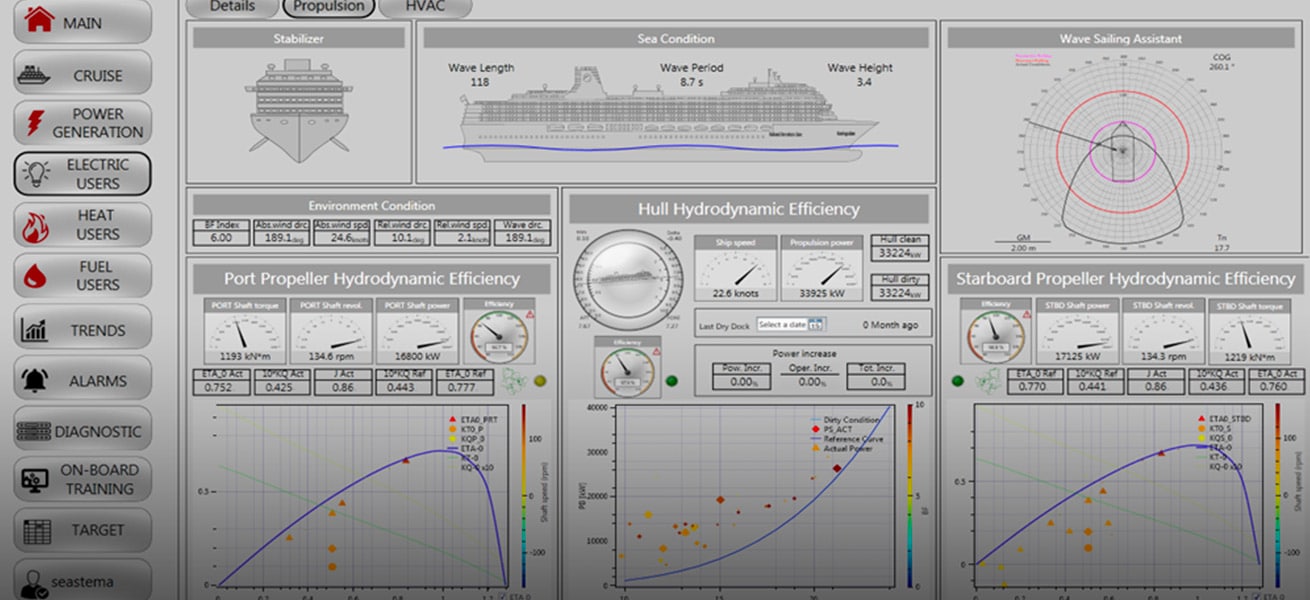

Particular attention is paid to the implementation of these control and supervision systems for the various sections of the hull and the entire ship.

Each functional logic is tested and simulated to eliminate any possible malfunction, the systems are designed according to the best safety standards and always guaranteeing hardware redundancy to avoid any possible danger.

The systems implemented control each subsystem of the ship and are interconnected between locals for centralized and user-friendly management by the operators.

The use of DCS and PLCs from the best international players allows us to offer cutting-edge solutions with proven technologies, synonymous with guarantee and quality.

The control systems created are then integrated on SCADA of different nature, including proprietary ones, allowing simple and SMART management of the ship system.

The creation of auxiliary HMIs allows operators to act directly on certain sub-systems even away from the centralized control room, providing the possibility to intervene in a timely and precise manner.

We collaborate with international clients including Seastema for the construction of management and control systems for military ships where the approach is mainly mission-critical.

We provide support both for the implementation of command and control logics, testing and debugging of the system up to commissioning on the ship before delivery.

A structured and tested production chain for years now allows us to offer a product with high added value, based on experience, quality and the human factor, fundamental in every project.

Our works are now present all over the world, discover the latest projects by clicking here.